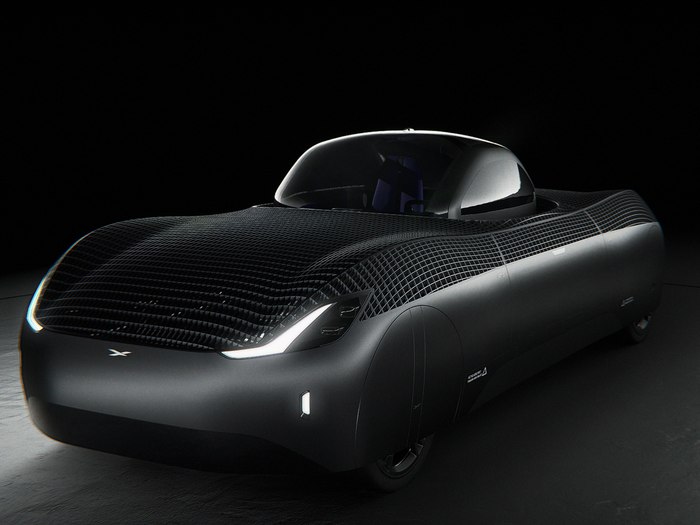

Electric vehicles (EVs) are in an entrancing period of improvement. While their heart, the lithium-particle battery, has seen costs drop fundamentally, EVs all in all stay expensive.

Less expensive unrefined components and Extended creation added to the decrease in costs

10 years prior, the normal expense of a lithium-particle battery was $780 each kilowatt-hour. Starting around 2023, this has plunged to a record low of $139/kWh, as indicated by the Bloomberg New Energy Establishment (BNEF). This lessening is generally because of extended creation and less expensive unrefined components. However, notwithstanding these expense decreases, EVs haven’t become fundamentally more reasonable for the typical buyer. Why?

To begin with, the decrease in battery costs doesn’t promptly mean less expensive EVs. Fabricating an EV is a capital-serious cycle, with various costs past the battery. Indeed, even with less expensive batteries, automakers actually face high creation costs.

Second, the EV market hasn’t extended as quickly as expected. This more slow development implies that the high interest in EV creation hasn’t paid off true to form, prompting greater costs for purchasers. For example, in 2022, battery costs really expanded momentarily because of a befuddle among organic market.

Moreover, automakers are mindful in moving expense decreases to shoppers. Brands like General Engines and Portage have confronted postpones in their EV rollout because of economic situations and the requirement for mechanical upgrades. This demonstrates a bigger issue: the EV business is as yet tracking down its balance in a and developing business sector.

Be that as it may, there’s a silver lining. North America is quickly developing as a battery fabricating center, reinforced by legislative help. With expanded homegrown creation and interest in battery innovation, what’s in store looks encouraging.

Topics #battery #Electric Vehicles #EV #ion battery #Lithium